Mercedes hybrid system repair demands meticulous precision, specialized technicians, and advanced tools for accurate diagnostics and component replacement. This rigorous process ensures optimal energy distribution, maximizing fuel efficiency and preserving advanced technology. Quality assurance involves inspecting every component, using diagnostic tools, and adhering to stringent industry standards, with continuous training and equipment calibration crucial for passing final QA. Mechanics must address issues like loose connections or faulty sensors to maintain peak performance and efficiency of the hybrid system.

In the realm of automotive innovation, Mercedes hybrid systems stand out as a sophisticated fusion of power and efficiency. As these complex mechanisms age, expert repair becomes paramount. This article delves into the intricacies of Mercedes hybrid systems, exploring their components and functionality. We emphasize the critical role of quality assurance in hybrid system repairs, offering a comprehensive guide for mechanics to ensure optimal outcomes. Understanding final QA processes is essential for maintaining these cutting-edge vehicles’ performance and longevity.

- Understanding Mercedes Hybrid Systems: Components and Functionality

- The Importance of Quality Assurance in Hybrid System Repairs

- Passing Final QA: A Comprehensive Guide for Mechanics

Understanding Mercedes Hybrid Systems: Components and Functionality

Mercedes Hybrid Systems are complex, sophisticated mechanisms designed to blend powerful electric motors with traditional internal combustion engines for enhanced fuel efficiency and reduced emissions. Comprised of various interconnected components, these systems demand meticulous precision during both initial manufacturing and subsequent repairs. Core elements include the electric motor, battery pack, power electronics controller, and hybrid transmission. The seamless integration of these parts allows for intelligent energy distribution, optimizing performance and efficiency across different driving conditions.

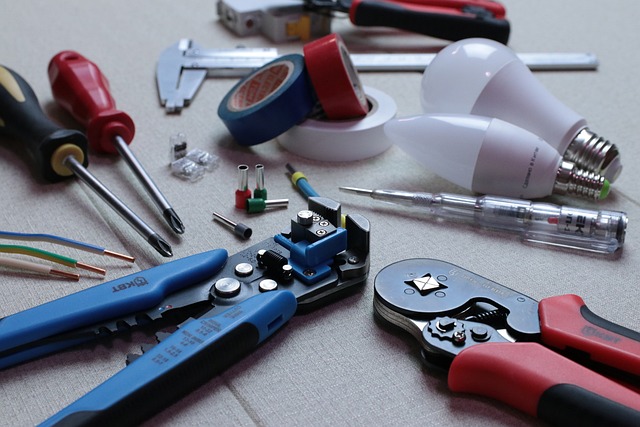

When it comes to Mercedes hybrid system repair, expertise is paramount. Specialized technicians must possess in-depth knowledge of these intricate systems to accurately diagnose issues, replace faulty components (like those requiring car dent repair or vehicle body repair), and ensure the restored car operates at peak efficiency. A high-quality car body shop equipped with advanced tools and a deep understanding of hybrid system functionality is essential for ensuring both performance and longevity of these cutting-edge vehicles.

The Importance of Quality Assurance in Hybrid System Repairs

In the realm of Mercedes hybrid system repair, quality assurance is paramount. It’s not merely about fixing components; it’s about ensuring the intricate interplay between electric motors, batteries, and internal combustion engines functions seamlessly and efficiently. A rigorous quality assurance process guarantees that every repair meets not just industry standards but also the exacting specifications of Mercedes-Benz. This is crucial for maintaining optimal performance, maximizing fuel efficiency, and preserving the advanced technology that defines hybrid vehicles.

When it comes to car collision repair or frame straightening in hybrid cars, specialized training and equipment are essential. Auto bodywork experts must understand the unique challenges posed by these sophisticated systems. Proper alignment, precise fitting of components, and careful handling of sensitive electrical systems are non-negotiable. Only through comprehensive quality assurance can repairs be trusted to restore a Mercedes hybrid vehicle to its original state, ensuring it continues to deliver the innovative performance that made it a choice for eco-conscious drivers.

Passing Final QA: A Comprehensive Guide for Mechanics

Passing Final QA for Mercedes hybrid system repair is a meticulous process designed to ensure the highest level of quality and performance. Mechanics must be prepared to conduct thorough checks on every component, from the battery systems to the electrical connectors. This involves verifying proper functionality through diagnostic tools, ensuring all parts are in optimal condition, and confirming seamless integration with the vehicle’s existing systems.

A comprehensive guide for mechanics includes understanding Mercedes’ specific protocols, utilizing specialized training and resources, and paying close attention to detail. Regular calibration of equipment and staying updated on the latest technical advancements in hybrid technology are crucial. Moreover, mechanics should be adept at identifying and addressing any potential issues, such as loose connections or faulty sensors, which could impact the overall performance and efficiency of the hybrid system, akin to meticulous car damage repair or bumper repair work.

Mercedes hybrid system repair requires a meticulous approach, especially when it comes to quality assurance. By understanding the intricate components and functionality of these systems, mechanics can ensure optimal performance and safety. Passing final QA is not just a checkmark; it’s a commitment to maintaining the high standards set by Mercedes-Benz, guaranteeing customers a reliable and efficient driving experience. A comprehensive guide for mechanics emphasizes every step necessary to achieve this, making Mercedes hybrid system repair a precise science.